SERVICES & PRODUCTS / Corr-Ze™ Surface Treatment Systems

KDM Marine is a representative for the Corr-Ze™ range of anti-corrosion products.

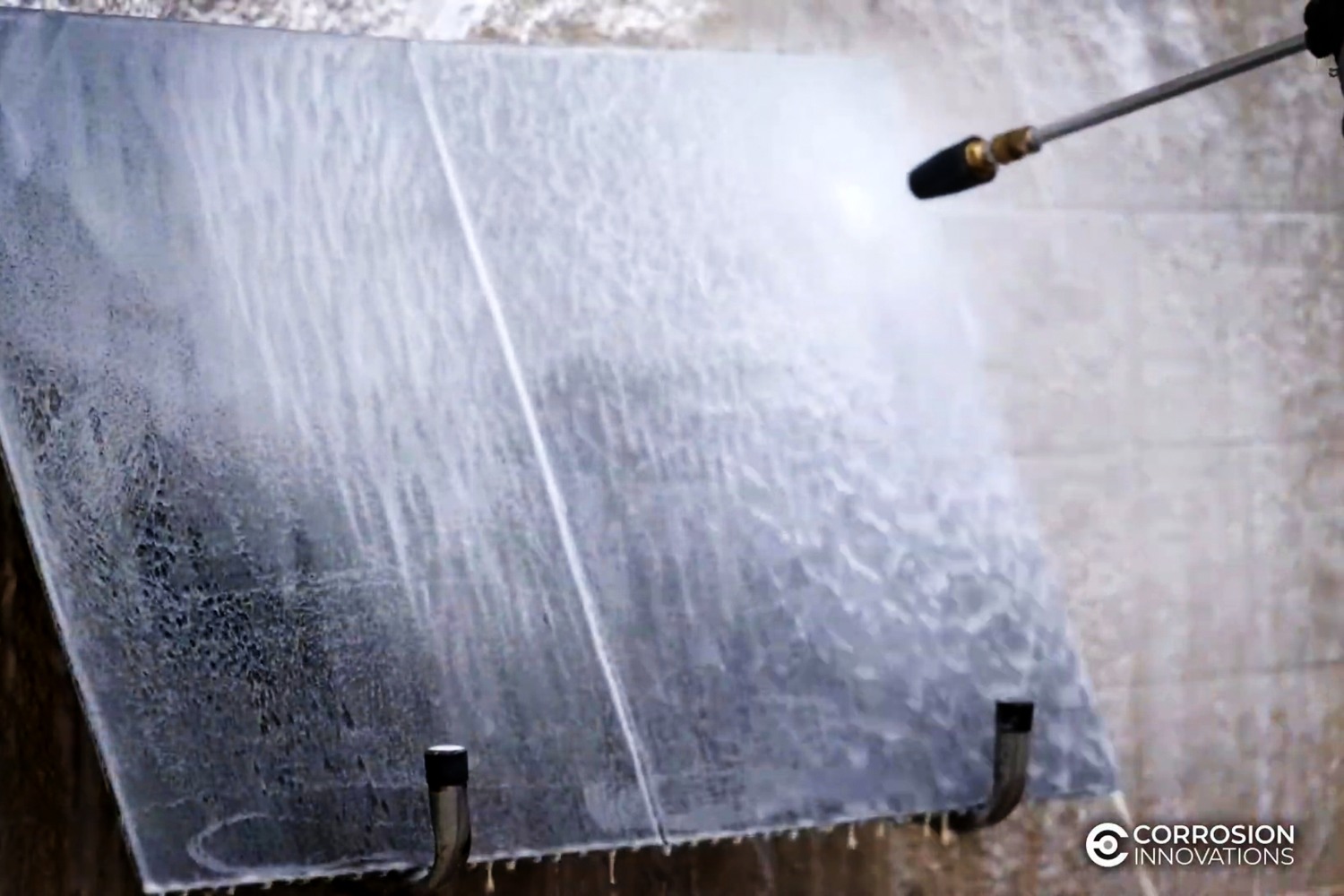

Corr-Ze is a metal surface preparation which removes soluble salts and contaminants prior to coating, preventing corrosion and improving coating adhesion.

The Problem

- Traditional blasting methods leave behind harmful contaminants.

- Traditionally, coating must happen immediately following blasting, to prevent flash rusting.

- Inclement weather shuts down coating operations, resulting in re-blasting being required.

- All these issues cause significant delays and increased costs.

Corr-Ze™100 and Corr-Ze™200 are the ultimate corrosion cures, going beyond the microscopic level to guarantee improved coating adhesion and prevent under-film corrosion.

Corr-Ze 100

- Use as additive in UHP or wet abrasive systems

- Reduces levels of salts present after blasting

- Leaves No Film

- Imroves Bond Strength of Coating

- Prevents Flash Rust

- Water Based

- Non-Flammable

- Fast Drying

- Non-Toxic, Environmentally Friendly

Benefits

- Reduces Project Costs

- No Need to Coat Same Day

- Extends Coating Life

- Reduces Downtime

- Reduces Maintenance

Applications

- Apply to a wide range of substrates

- Offshore structures

- Pulp & Paper plants

- Bridges

- Atmospherically exposed environments

- Marine & Immersive environments

Corr-Ze 200

- Apply with brush, roller or spray gun

- Acidic gel totally removes all salts

- Rinse off with Corr-Ze 100

- Removes Flash Rust

- Non-Toxic, Environmentally Friendly

Benefits

- Reduces Project Costs

- Limits downtime

- Continue to blast in inclement weather

- No more rework blasting due to rust

Corr-Ze 100 Datashaeet

Corr-Ze 100 Datashaeet